We don’t need to tell company leaders how significant their labor costs are. Their financial statements do that for them. But whether it’s a priority of theirs or not, the benefits of reducing labor costs can be invaluable.

Labor costs are widely recognized as one of the highest expenses companies must manage. Varying in industry, size and revenue, there’s no standard cost per company. This has been further complicated by persistent fluctuation in wages and salaries through labor laws.

With changes to the Fair Labor Standards Act (FLSA) in January 2020, companies must now pay up to 1.5 times the rate for any overtime hours worked over a 40-hour workweek. In conjunction, the U.S. Bureau of Labor Statistics reported that wages and salaries have increased by 1.1% and benefit costs 0.9% through the final 3 months of 2021.

According to SHRM, rising wages have been driven by widespread labor shortages and higher inflation in the last two years. Subsequently, this has led to an increase in wage demands. These desperate times are forcing employers to offer more benefits to lure new recruits while trying to maintain their current workforce.

But for others, they’re finding it increasingly difficult to find a best-fit schedule for the ever-changing demand. In industries such as healthcare and hospitality, understaffing and overstaffing are becoming common problems that need to be solved. All of these issues are resulting in increased labor expenses that need to be reduced.

But before we look at ways to reduce labor costs, let’s break them down a little more first.

What exactly are labor costs?

Labor costs are the price an employer pays for their employees. The costs can be broken down into direct and indirect costs. Direct costs are associated with the cost and benefits of employees who are directly involved in producing the product or service. Whereas indirect is based on those who support it.

- A direct cost could be a manufacturer, assembler or delivery driver who have had a direct involvement in producing the product and distributing it through the supply chain.

- An indirect cost relates to the employee playing a non-essential role in the production of the product. This could be somebody working in administration or finance.

Essentially, labor costs help companies to distinguish an acceptable price for their goods based on the price they’re paying to create and service them. Many perceive the benchmark for a labor ratio to be 20-35% of their overall gross sales. But if you’re not achieving the target you desired, how best can you put it right?

Reduce reduce reduce!

We’ll say it loud and clear. Reduce your labor costs!

Before you ask, we’ll tell you how. Automation. New technologies mean companies can manage and reduce their labor costs much more efficiently, while also increasing productivity. And thankfully, you probably won’t need to decrease headcount or benefits.

How to reduce your labor costs using Automation

TRACK YOUR SPENDING

Let’s begin with the most obvious.

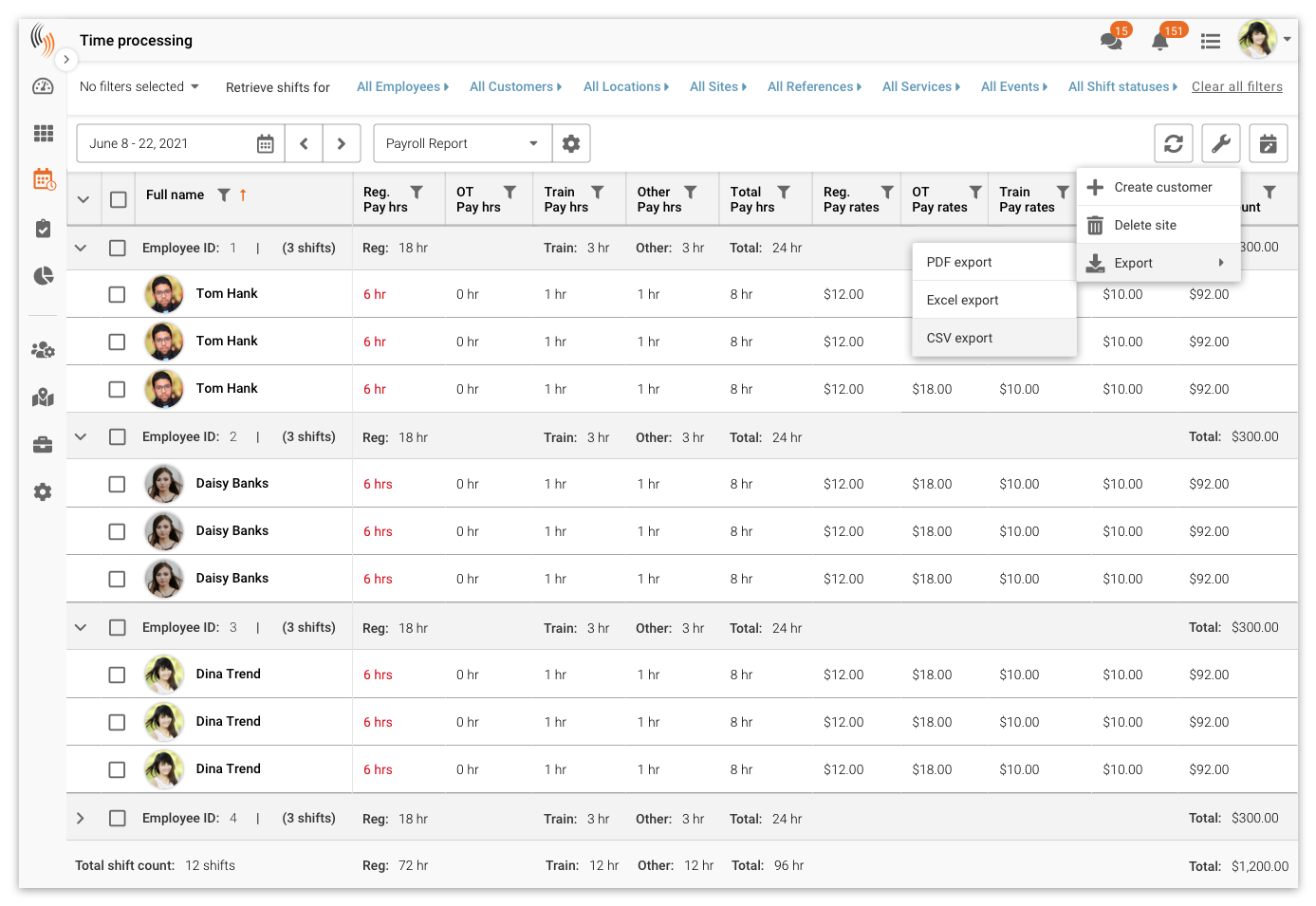

Whether it’s payroll, employee scheduling, or analytics software you choose to use, make sure it provides the all-important metrics. These include;

- Total payroll costs

- Payroll taxes

- Overtime

- Sick days/absences

- Cost of benefits

You can’t forecast your labor without these metrics. And without forecasting your labor, you’ll have no idea how you can reduce your labor costs. As champions of easy-to-use employee scheduling software, we know the benefits of utilizing your data. A single report is enough to inform you of what is valuable and what is not.

Incompetency such as overstaffing can continue to put an unnecessary dent in your budget. You should look to integrate the correct scheduling software to discover and resolve trends. By evaluating these trends against your once trustworthy labor forecast, you’ll soon figure out how coherent your schedule is. Maybe that additional employee you scheduled on-site was never needed after all.

Automation is the easiest way for business owners to gather and utilize the data they need to track their spending. Employee scheduling software like Celayix can help you see all of your workforce management data as costs, which can help you make better decisions.

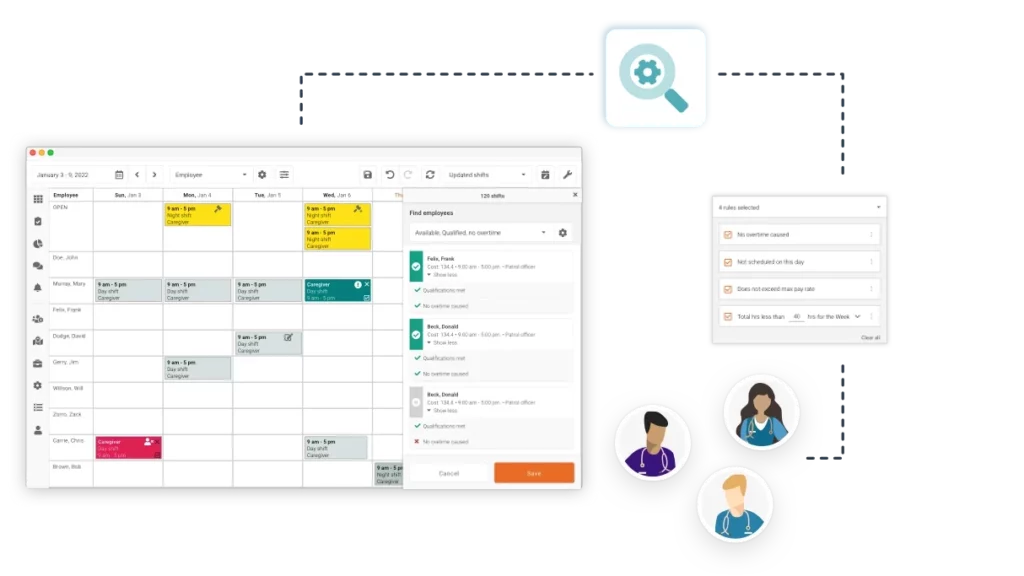

OPTIMIZE EMPLOYEE SCHEDULING TO REDUCE OVERTIME

One of the simple ways to reduce and control labor costs is by reducing overtime. It doesn’t take a genius to know that overtime vastly increases labor costs. We don’t think you should a stop to overtime altogether. It often helps companies deal with short-term variations to cope with demand.

The additional hours can be hugely beneficial for employees’ bank balances too. But by optimizing your schedule, you’ll have more visibility over the productivity of the workforce. And therefore, can make the right decisions in the company’s best interest. But how best can they achieve this?

It can also help boost the productivity of your workforce by allowing you to assign the most qualified, cost-effective candidates to shifts as needed. You’ll soon come to realize the amount of overtime you’re scheduling may not be needed, or how it could be better spent on a new full-time recruit.

ELIMINATE INEFFICIENT PROCESSES

To reduce your labor costs, you must first eliminate processes that are driving poor performance. Manual processes appear to be a root cause of this. They’ve been proven to facilitate wasteful and time-consuming practices. And this is what lands many companies with unexpected and often inflated labor costs.

But it’s not just the labor costs that feel the damage. Inefficient processes can also lead to a decrease in employee morale and productivity. This can result in consistent employee turnover – which could be considered an indirect labor cost. Managers – it’s time to look away now.

HRreview reported that it costs up to $30,614 to replace a single employee. This includes costs such as recruitment, hiring, and training new starters to gain maximum productivity. So how can they stop this from becoming a regular theme?

The State of Workflow Automation Report highlighted that 62% of survey respondents reported three or more process inefficiencies that automation could solve. This statistic highlights the importance for managers to seek software automation to reduce labor cost errors.

Maybe you’re writing shift changes on a piece of paper. Or maybe you’re emailing your weekly schedule to 1000+ employees. Whatever method you’re using, if you’re reading this blog there’s a chance it’s not working. If it’s not, then we suggest turning to a method of automation to ensure you don’t miss a trick.

Software automation eases the burden of inefficient processes that are hampering your company’s performance. Improving these processes can reduce labor costs and also reduce employee turnover.

AVOID THE OBVIOUS THREATS

Unfortunately, manual processes won’t stop time theft. But an automated time and attendance process can.

As advocates of best-of-breed time and attendance software, we know how effective it can be to a company. Especially when productivity levels seem unusually low. Our software allows you to monitor all employee time, labor and punches. You can apply geofences to sites to ensure your employees are where they say they are when they check in/out of shifts.

You can also input break periods that require check-in and out to stop employees from taking extended breaks during work time. But as customizable as our software is, it’s made even greater with the ability to integrate other software where necessary. Enter time clocks.

TIME CLOCKS

Outdated time clocks, an essential technology for companies are susceptible to buddy punching. Buddy punching is when a coworker clocks in for another employee. And this costs companies millions in labor costs per year.

The solution to reducing your labor costs comes in the form of automated and integrated time clocks. Biometric time clocks, to be precise. Biometric time clocks require a form of identification to ensure that an employee is who they say they are.

Typically, it’s through fingerprint or facial recognition. Time clocks can also work in sync with employee scheduling software. Through this integration, actual hours worked are automatically sent to your employee scheduling software and attendance matching means you only pay for work hours that are really worked.

We’ve spent a lot of time discussing time theft. But it’s also important to be aware that time theft often comes from employees feeling detached from and disengaged in their role. The question is, can automation play its part in changing this?

DRIVING EMPLOYEE ENGAGEMENT

While it may seem counterintuitive, automation can drive employee engagement within the workforce. With the best technology, employees will feel more connected with their role and valued by their company. It can also propel them to operate at their highest level. This means they can be trusted to complete their job at hand in an efficient and timely manner.

Automated employee scheduling software can help schedulers send out shift reminders, schedule updates and help employees self-schedule their shifts – all of which can boost employee engagement.

There are a million ways you can use automation to reduce your labor costs. But if you play your part, your employees will play theirs.

How can automation help to reduce your labor costs?

From our research, automation undoubtedly plays a significant role in achieving labor cost savings.

When we assess the average company, it’s guaranteed that at many points in any given day they’re using automation. But those who feel their labor costs are beyond their budget, need to utilize these technologies for support. Countless software such as employee scheduling, payroll, HR, and time clocks, when used correctly, can make a big impact on the money you spend on your labor.

More importantly, they can assess the value of the money you’re spending. Whether you’re happy or unhappy with what you discover. You’re actively planning to avoid or combat a problem.

If you’re in a situation where you’re spending unnecessarily on labor costs, consider what can be automated to save both money and time when it comes to your workforce. If you want to hear how Celayix workforce management software can help you lower your labor costs, request a Cost-Benefit analysis here!