When you run a manufacturing business, effective control over the production process is vital for ensuring the efficiency and productivity of operations. This is where a manufacturing management system (MMS) comes into play. In this blog post, we delve into the realm of MMS, their importance, benefits, and some of the industry-leading solutions.

Understanding Manufacturing Management Systems

While advances in technology have vastly improved manufacturing processes in recent years, most manufacturers haven’t taken advantage of their own data to improve their productivity. The best way to do that is with a manufacturing management system.

A Manufacturing Management System is a software solution designed to help businesses oversee their production processes, from the planning and scheduling stages to the execution and post-production analysis. These systems give a holistic view of the manufacturing operations, providing valuable insights to facilitate informed decision-making. It allows businesses to maintain control over their production process, inventory management, quality control, and much more.

Why are Manufacturing Management Systems Important?

In the competitive world of manufacturing, having an edge can make all the difference. MMS provides this edge by optimizing the production process and increasing overall operational efficiency.

Facilitating Decision-Making:

Manufacturing management systems can provide real-time data about various aspects of the manufacturing process. This data can be analyzed and used to make informed decisions, leading to better planning and increased productivity.

Optimized Resource Utilization:

MMS helps optimize resource allocation by providing a clear picture of the available resources and their current usage. This helps in reducing waste and ensures maximum efficiency.

Improved Quality Control:

With MMS, monitoring and managing the quality of production becomes easier. It helps detect issues early in the process, thus preventing potential losses and ensuring customer satisfaction.

Manufacturing Management Systems impact Profitability

Manufacturing Management Systems (MMS) can significantly impact the profitability of manufacturing companies by driving operational efficiency, reducing waste, and improving decision-making. MMS provides real-time visibility into the manufacturing process, enabling accurate demand forecasting and efficient resource allocation. By minimizing overproduction, reducing material waste, and effectively managing inventory levels, companies can significantly cut costs and increase their bottom line. Additionally, the enhanced quality control mechanisms in these systems prevent costly rework and returns, ensuring customer satisfaction and repeat business. Moreover, the data-driven insights obtained from these systems aid in strategic decision-making, potentially opening new avenues for revenue growth.

One of the most effective ways to use a manufacturing management system to improve profitability is with predictive maintenance. By assessing the historical performance data of machinery, predictive maintenance can forecast potential failures. This minimizes downtime and helps to identify the underlying cause of the issue. Predictive maintenance typically reduces machine downtime by 30-50% and increases machine life by 20-40%.

Manufacturing Workforce Management Systems

While MMS focuses on the operational aspect of manufacturing, Manufacturing Workforce Management Systems (MWMS) focus on managing the human element of the production process. These systems aid in employee scheduling, time and attendance, task management, and labor forecasting.

MWMS can significantly enhance productivity by reducing manual labor scheduling, improving communication between management and employees, and reducing labor costs through effective resource allocation.

Celayix provides manufacturing workforce management software, and is designed with the needs of complex industries like manufacturing in mind;

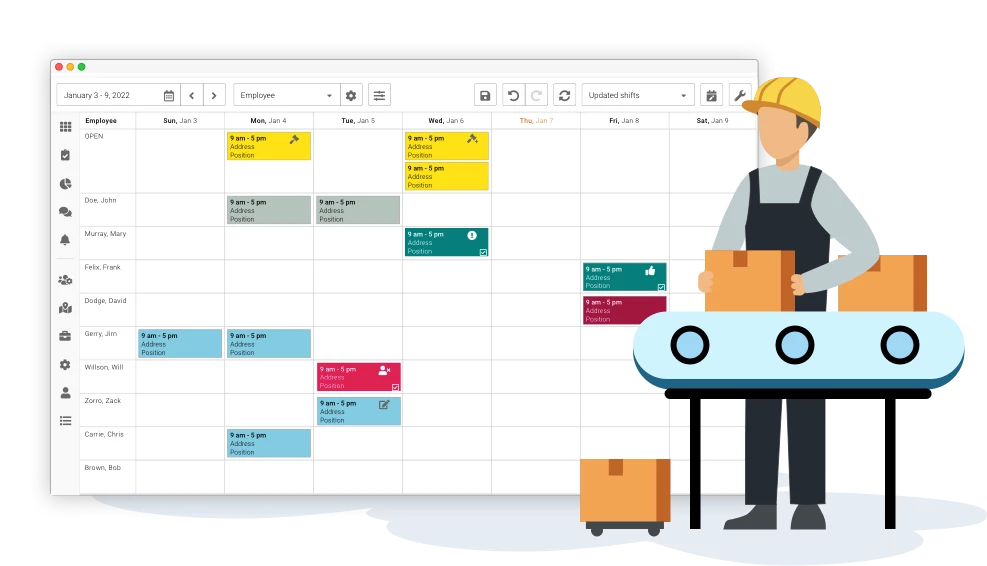

Efficient Scheduling: Celayix’s advanced scheduling software can help you create and manage shift schedules easily, reducing the time spent on manual scheduling. It takes into account employee availability, skill sets, and labor laws to ensure optimal shift allocation. You can set up locations for each section of your production line and view them individually, or view the whole organization in one view for a holistic overview.

Real-Time Communication: With Celayix, you can improve communication with your team. Instant notifications and alerts keep everyone informed about schedule changes, resulting in fewer no-shows and improved productivity.

Artificial Intelligence: Our software uses artificial intelligence to review your historical scheduling data and create completely optimised schedules based on your business needs. Create a schedule, run it through our AI tools, and see improvements where they are possible!

Overtime management: Overtime is a hot topic when it comes to manufacturing. It’s often offered to workers to improve production levels, but that eats into profitability. Celayix allows schedulers to eliminate reduce unnecessary overtime without impacting productivity! We’ve helped manufacturers save over $100,000 in overtime costs through employee scheduling alone!

If you’d like to learn more about Celayix manufacturing management systems, check out a free live demo today!